A Bit of History

Coffee machines have changed deeply with the appearance of the coffee capsules, not only at home.

The history is interesting: apparently, the idea of coffee capsules was developed at Nestlé in the 70's, but it did not pick-up as business. A second trial in the 80's created Nespresso, which signed contracts with appliance manufacturers to design elegant machines, while Nespresso maintained the name and the supply of the capsules. This confluence created a boom in the market etc.

Here the story from Nestlé's side.

The man-behind-the-idea seems to be

Eric Favre, not mentioned in the previous link. An engineer at Nestlé, he moved away and created his own company, Monodor, also working on the capsule business (later bought by a

Brazilian firm).

Here his account.

While in Europe and Asia Nespresso is leader, it seems that in the USA Keurig (K-cups) is their equivalent. There seem to be some design differences between the cups, and one important is that while Nespresso's are made with aluminium, K-cups are in plastic, which raises issues for both.

Here a short comparison between the two leaders, and

here an article on the recycling issues.

Krups XN 2001

I found this machine thrown on the street: it was missing the receptacle for the capsules, the drip grid and the water tank, but I picked it!

The machine is from

Krups, model XN 2001:

The model seems to be retired from production (

Amazon), although spares are available (f.eg.

here and

here).

I have not found the manuals, but these seem to be close enough:

Essenza C91,

Essenza C99 and

Essenza C100.

Disassembling

Although I didn't intend to use it as a coffee machine, I tried to dismount it cleanly. The base has the usual message saying that there are no serviceable parts inside etc., and the plastic parts are attached with what initially seemed to me rivets. I was surprised because even at the repair workshops a rivet is hard to remove, but I though that the high pressure inside might require extra safety.

So, I broke the covers...

... Now I have found that they are screws, not rivets, and that they can be hacked (

here and

here). The special screws can even be bought in

Amazon!

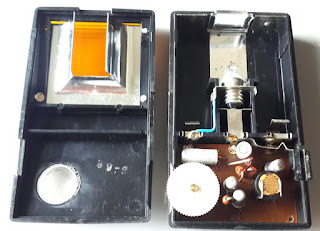

Some pictures of the disassembling process and parts:

The final result after removal of all supporting and protecting elements and the pipes:

Main Parts

The machine has mechanical, hydraulic and control systems, in four main parts:

- A pump, which receives the water from the water tank and pumps it into a boiler,

- A boiler, which creates a pressurized flow of hot water and steam,

- The piston which compresses the coffee capsule and allows the water to go through it,

- An electronic motherboard, with sensors and switches on the other parts.

Schematics

Without the details of the mother board (see below):

Parts

Vibrating Pump

The pump is of the vibrating or solenoid type, from Invensys, model CL7.

The operational principle can be seen in

this video. The reason why such pump type is selected (which I never had heard of before) is probably the size and the pressure they can deliver, as explained in

this other video.

Invensys, an Italian company, used to be part of

Schneider Electric, an European giant, and was purchased in 2011 by

ARS, a specialist firm.

The model of the machine seems to be out of production. I have not found the datasheet, but

these ones from ARS might be similar.

Neither the pressure nor the volume flow is indicated in the label. From ARS' datasheets it seems that this pump can provide 200 ml/min against a back-pressure of 10 bar. It is also self-priming.

Interestingly, it requires 1.5-2 min off for each minute of operation, probably due to overheating. (It is worthy noting that the manuals don't mention this).

A temperature fuse is attached to the body of the pump. It is labelled: "MICROTEMP SVABGB E5A00 Tf 128 C". The specifications of these fuses can be found

here. Although the coding seems to be modified, the fuse seems to have a nominal amperage of 20 A, and a functioning temperature of 128 ºC (which I find both surprisingly high: if the body of the motor is at 128 ºC, how hot will it be inside before the fuse works?)

Boiler/Heater

It is an aluminium body with a plastic base, and a series of connectors. The base can be removed (it is screwed) but the chassis is in one piece.

On the chassis it is labelled as EF1308, 230V 1200W. I have not found any other information.

The water inlet is on the top (of the picture), and the outlet at the bottom, in opposed corners of the chassis. Both are in brass-like alloy, 4 mm outer diam.

Close to the inlet and outlet, and at a slight angle, there are the connecting ends of what seems to be the heating resistor (measured approx. 50 ohm, or 4.9 A for the nominal 1200 W mentioned in the chassis and one of the sheaths of the resistor).

The line (brown cable) and neutral (blue cable) are connected (thermally) to the chassis through sheathed thermal fuses similar to the one described above (but here Tf=167ºC).

The chassis is grounded. This is the only piece of the machine which is grounded, which I find surprising considering that it handles liquids.

Finally, in one corner of the chassis another sensor is fixed, likely to measure temperature (perhaps an NTC thermistor within the body of a bolt).

The water is transported through flexible pipes with quick fittings:

The Piston

The piston mechanically, manually, compresses the coffee capsule and places it into a suitable socket. It also perforates the capsule and allows the hot water/steam pumped through the boiler to lixiviate the coffee and fall into the cup through the beak.

There is no sensor for the correct positioning of the capsule or the closing of the receptacle.

The Motherboard

The motherboard has some separated groups:

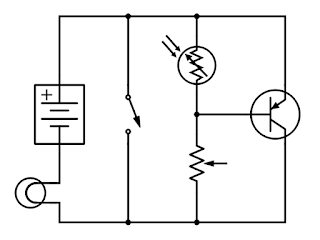

- The heater resistor is fed from a

triac in

TO-220 package attached to a large heat sink. It is labelled as BTB12 600BW from ST. The datasheet is

here. The gate of this triac is controlled from a microcontroller PIC16F676 whose datasheet is

here.

- The pump is controlled from a small triac BT134W in

SOT-223 package. The datasheet is

here. Main terminal 2 (4) is directly linked to the pump, while terminal 1 goes to line, with a 220 uF electrolytic capacitor in parallel. The gate goes through SMDs that I cannot completely track (but see below).

- The power line is also protected with a capacitor CV75K10 (varistor, from Keko; datasheet

here).

- Two additional film capacitors type PCX2 337 MKII with 470 nF and 220 nF protect the microcontroller (

datasheet).

- The two moment touch switches are in separated modules, with rubber cups, and one LED in the selector of the coffee brewing.

I am not sure about several SMDs, and some connections may be missing, but the schematics of the motherboard (seen from behind) is probably something similar to this: